1988

- Started production of Railway tachographs in technical collaboration with Hasler AG, Switzerland

1989

- Set up R&D centre at Noida

1992

- Started production of Protection Relays for Indian Railways in technical collaboration with Secheron SA, Switzerland

1993

- Recognition of R&D Centre by Government of India

- Started production of Wheel Flange Lubricating System for Indian Railways in technical collaboration with Secheron SA, Switzerland

1994

- Obtained ISO 9001 certification

1996

- Started production of Online Uninterruptible Power Supply Systems upto 40 kVA in technical collaboration with Powertronics SpA, Italy

1998

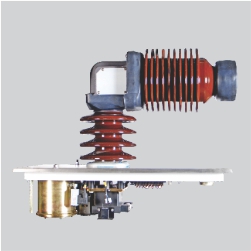

- Started production of Vacuum Circuit Breakers for Electric Locomotives and EMUs in technical collaboration with Secheron SA, Switzerland

- Relocated to a larger and modern manufacturing facility in Noida

1999

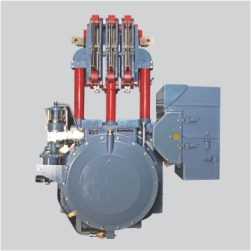

- Started production of 300 kVA GTO based Auxiliary Converter for Electric Locomotives (AC propulsion) in technical collaboration with Chittaranjan Locomotive Works, Indian Railways. [Technology from ABB (now Bombardier)]

- Started production of IGBT based Underslung Converter (DC to AC) for Passenger Coaches in technical collaboration with Hyundai Heavy Industries Co Ltd, South Korea

2000

- Started production of IGBT based Static Converter for Electric Locomotives (DC propulsion) in technical collaboration with Hyundai Heavy Industries Co Ltd, South Korea

- Started production of IGBT based Onboard Converter (DC to AC) for Passenger Coaches in technical collaboration with Hyundai Heavy Industries Co Ltd, South Korea

2001

- Started production of Electrical Circular Connectors for traction application in technical collaboration with Gimota AG, Switzerland

2002

- Started production of Passenger Information System for Indian Railways & Metro Railways in technical collaboration with Whiteley Electronics Ltd, UK

- Started production of IGBT based Underslung Converter (AC to AC) for Passenger Coaches in technical collaboration with Hyundai Heavy Industries Co Ltd, South Korea

2004

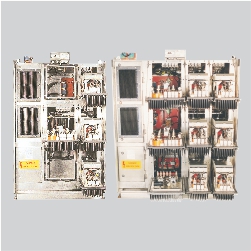

- Started manufacturing Onboard Electrical Panels for Delhi Metro under technical alliance with Daeyang Electric Co Ltd, South Korea

2006

- Inhouse designed and developed DSP based Efficient Controller (H/W & S/W) for 180kVA Auxiliary Converter used in Locomotives

- Signed technical collaboration agreement with Ganz Transelectro Vehicle Devices Ltd, Hungary for manufacturing of Onload Tap Changers for Electric Locomotives

- Signed technical collaboration agreement with Powertronix SpA, Italy for manufacturing of UPS Systems upto 2400 kVA (8×300)

- Signed agreement for joint development of specialised Switchgear items for traction application with Alfa Union AS, Czech Republic

- Signed technical licence agreement with Pixy AG, Switzerland for production of Onboard Diagnostic Terminal for Railways

2007

- Improvised Vacuum Circuit Breaker design & technology for enhanced reliability and applied for its patenting

- Inhouse designed & developed GPS based Passenger Information Display System for Railway Coaches

2008

- Technological improvement in design of various Onboard Data Acquisition Systemsby incorporating Field Programmable Gate Array (FPGA) Chip

- Initiated co-operation with Neurocom, JSC Moscow, Russia for manufacturing and selling of Driver Vigilance Telemetric Control System (DVTCS) to Indian railways

2009

- Inhouse designed & developed a range of DC to 3 Phase AC and DC to DC IGBT based Underslung Converters for Metro Railways

- Inhouse designed & developed LED based Destination Display Boards cum Passenger Announcement & Vehicle Tracking Systems for modern Buses

- Inhouse designed & developed GPS/GSMR compatible Public Information System for Bus-Q-Shelters

- Obtained TS 16949 certification for the Co's Display Systems range, meant for Automobile industry

2010

- Inhouse designed, Developed and Started production of Earthing Switches for Electric Locomotives and EMUs

- Inhouse designed, Developed and Started production of Master Controllers for 3 Phase AC Locomotives

- Inhouse designed, Developed and Started production of Key Multipliers Safety Interlocking system for Locomotives & EMUs

- Obtained CE & E Marking for the range of Display Systems, meant for Automobile industry

- Obtained Technical Approval from RDSO, Ministry of Railways for supply & installation of Heavy-duty Passenger Escalators at Indian Railway Stations

2011

- Selected by Railway Board, Ministry of Railways for its "Pilot Project" of design, supply & installation of Heavy-duty Escalators at its various Railway Stations, under consortium with Canny Elevator Co Ltd, China

- Entered into Technical Alliance with Elno Societe Nouvelle, France for Public Address System for networked Mainline and Metro Railway Stations & control centres

- Inhouse design and development of 1ø and 3ø unity power factor rectifier technology for ratings upto 500kVA

- Inhouse design and development of 2×500kVA Hotel Load Converter for Locomotive using Heat Pipe based thermal management

- Inhouse designed & Developed Vigilance Control Device for Electric Locomotives to supervise the alertness of driving crew for functions like throttle, master controller, horn, sander, loco brake, train brake, and various others

- Inhouse developed safety critical electronic modules for control system of Power Plant of Submarine confirming to MIL standards incorporating redundant logics / CAN Bus / RS485 Bus / MIL 1553 Bus

- Inhouse designed & developed 180kVA Static Converter with unity power factor rectifier used as Auxiliary Power source in conventional Locomotives

- Inhouse designed & developed MICAS-S2 Communication Interface with FPGA based hardware for 130kVA Auxiliary Converter used in 3-Phase Locomotives

2012

- Inhouse designed & developed main controlled unit (Dual Core-ARM+DSP based main controller) of On board Public Address / Passenger Information System used in Metro and Railways application

- Inhouse designed & Developed Hall Effect based Active Speed Sensor for Traction Motor

- Inhouse development under taken for 35kVA Underslung Converter for AC coach giving 40% more power with 30% less volume and weight thereby giving twice the power density

- Signed MOU with Societe De Constructions Electroniques Lilloise, France (Visionor) for joint development of TFT / LCD Displays for Indian Railway / Metro

2013

- Signed MOU with Ansaldo STS, Italy for joint development of high end Train Protection & Warning System (TPWS) for Indian Railway

- Obtained IPC-A610 & IPC / WHMA-A-620 Quality Standard Certification in PCB & Electric Assembly area

2014

- Expansion of production facility for new product lines, thus adding another 4600 Sq. m. floor area.

2015

- Obtained Environment Management System in accordance with ISO 14001:2004 and Occupational Health and Safety Management System in accordance with OHSAS 18001:2007

2016

- Inhouse designed, developed and started production of 3×130kVA Auxiliary Converter for IGBT based Three Phase AC Locomotives